The soil bacterium Cupriavidus necator has attracted the attention of researchers and industry for decades. This is partly because, through biochemical reactions, the bacterium converts the renewable raw materials formic acid and carbon dioxide (CO2) into valuable products such as bioplastics.

However, there is a drawback: the bacteria do not grow well on formic acid. The soil bacteria first burn the formic acid into more CO2, which they then reprocess by pumping in extra energy. A rather inefficient detour, according to microbiologist Nico Claassens. “It is like taking an extra lap around the starting line at a race.”

This could be more efficient, thought researchers from Wageningen University & Research and the Max Planck Institute in Germany. They designed a smarter, more direct biochemical pathway on paper—one that allows the bacterium to use formic acid directly, without unnecessary intermediate steps. This approach has now proven successful in practice. The results are published in Nature Microbiology.

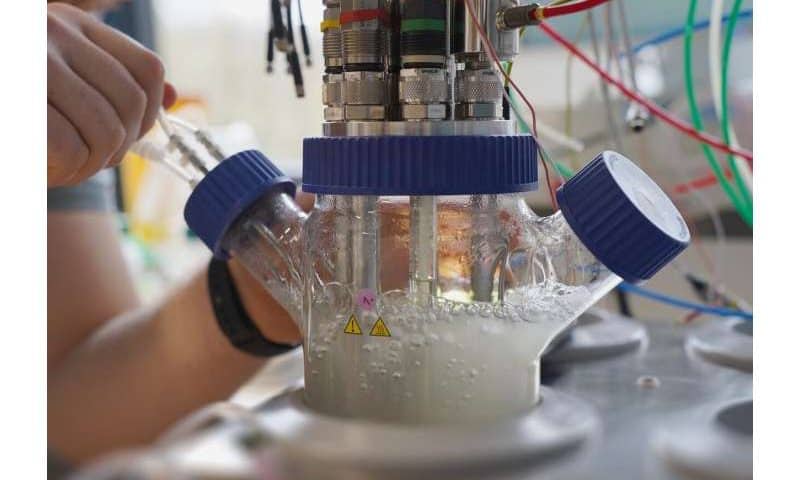

Beau Dronsella (Max Planck) observed that in small culture vessels, the bacteria yield 15% to 20% more biomass with the same energy intake. “We have shown that we can do better than nature,” says Claassens. He adds, “Twenty percent extra product may seem small, but it can make the difference between an economically feasible and unfeasible sustainable process.”

A ‘metabolic heart transplant’

Improving the bacterium required precise genetic modifications, or as Claassens calls it, a “metabolic heart transplant.” The researchers deactivated the genes responsible for the original, inefficient metabolic pathway and instead provided the bacterium with genetic instructions for the shortened route.

Think of the process as a factory with a conveyor belt on which raw materials are placed and processed by robotic arms—cutting, assembling, and gluing components together. Claassens and his colleagues replaced these robotic arms with more efficient ones, allowing the same final product to be made with fewer steps and less energy.

Cupriavidus necator already naturally produces useful compounds. Under the right conditions, it accumulates bioplastics in its cells, sometimes making up more than half of its body weight. The newly enhanced bacteria in turbo mode are particularly interesting to researchers.

“By altering their genetics further, we can direct them to produce other valuable compounds as well,” Claassens explains. However, the research is not quite there yet. “We have now demonstrated that the principle works.”

The next step is to use these modified bacteria to actually produce specific products. A startup has already shown interest in using the bacteria to manufacture chemicals from formic acid.